Experimental and CFD Investigation of shear on Electrocoalescer performance.

Authors and Affiliation

Pranav Lohar & Dr. Pramod Kothmire

School of Mechanical Engineering, MIT Academy of Engineering, Alandi, Pune.

Abstract

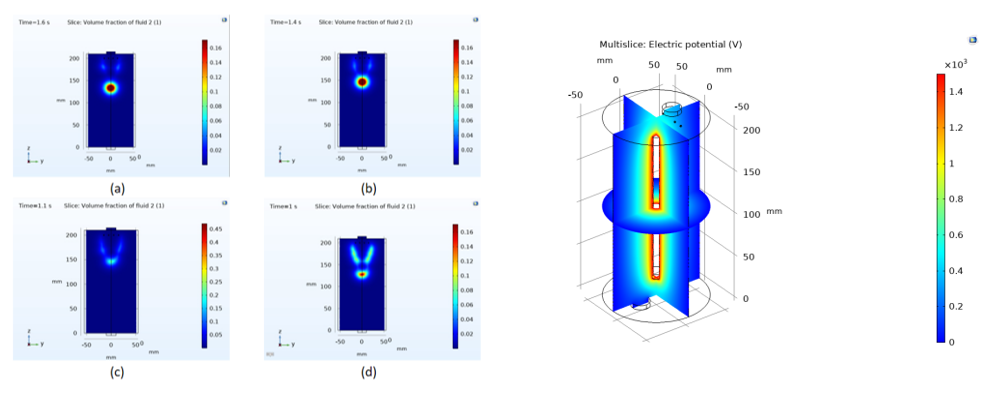

In the pursuit of efficient and sustainable fluid phase separation, this study delves into the intricate interplay of fluid mechanics and electrical forces in electrocoalescence. Anchored in the historical strides of this field, the research addresses critical knowledge gaps through a comprehensive experimental and numerical investigation. A model consisting of a central live electrode enveloped by a grounded hollow metal cylinder is employed to facilitate the coalescence of oil-water mixtures extracted from crude oil sources. The experimental results reveal the remarkable efficiency of electrocoalescence. At a flow rate of 3 LPM and an electric field strength of 3 kV/cm, the initial 20% water content in the mixture dwindles to a mere 0.35% in a remarkably short 10 minutes. These quantitative findings emphasize the practical applicability of the approach in achieving swift and efficient water-oil separation. Furthermore, computational fluid dynamics (CFD) simulations unearth profound insights. Coalescence times decreased significantly at higher flow rates. At 3 LPM, in a 0.3kV/cm electric field, it reduced further to about 0.98 seconds. This remarkable reduction in coalescence time suggests the pivotal role of shear effects at higher flow rates, despite the shorter residence time within the electric field. This multifaceted study promises to advance both the fundamental understanding of electrocoalescence and its practical application in optimizing water-oil separation processes, paving the way for enhanced separation efficiency and sustainable separation technologies.

Methodology

Electrocoalescence is a phenomenon where dispersed droplets or particles in a liquid medium merge or coalesce under the influence of an electric field. This process occurs when the electric field induces surface charges on the droplets, causing them to move towards each other and eventually merge, leading to the formation of larger droplets.

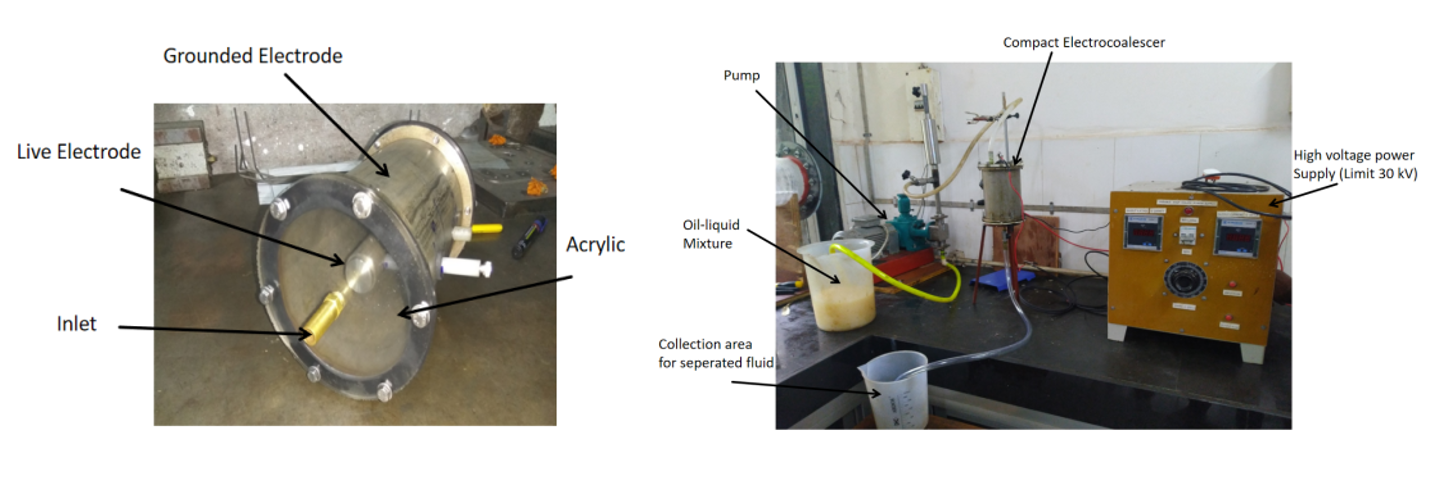

The experimental setup employed a cylindrical metal housing with transparent acrylic sheets for real-time observation, facilitating exploration of electrocoalescence phenomena.

A high-purity stainless steel electrode, precisely positioned within the setup, ensures stability and non-reactivity with the working fluid under a maximum 30 kilovolt electrical potential.

Systematic investigation involves varying operational parameters such as voltage, oil-water ratios, and flow rates, meticulously controlled to span different electric field strengths and fluid dynamics.

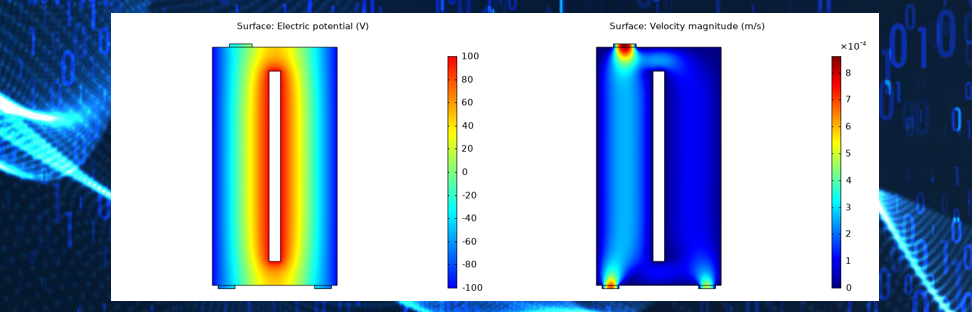

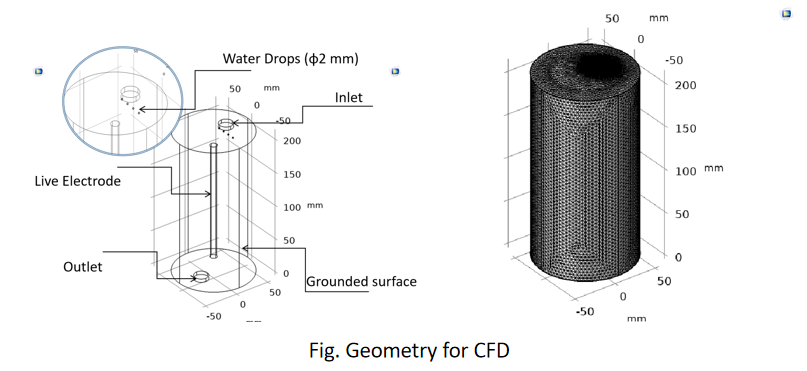

Comsol Multiphysics is utilized for Computational Fluid Dynamics (CFD) analysis, complementing experimental data to provide comprehensive insights into the electrocoalescence process.

Objectives

- How does the presence of water present in emulsion in compact electrocoalescer affect the coalescence process, and how is it influenced by different electric field strengths?

- How does pre-heating the oil-water mixture influence electrocoalescence, and what are the changes in coalescence behavior and efficiency?

Findings and Conclusion

Experimental analysis demonstrated rapid reduction of water content, with a 20% initial water content diminishing to only 0.35% within 10 minutes at a flow rate of 3 LPM and electric field strength of 3 kV/cm.

Numerical simulations aligned closely with experimental data, revealing the critical roles of flow dynamics and electric field strength in facilitating coalescence.

Higher flow rates were found to significantly promote coalescence, evidenced by a notable reduction in coalescence time as flow rates increased, as depicted in Computational Fluid Dynamics (CFD) results.

Insights gained provide crucial understanding of parameters influencing electrocoalescence, contributing to the optimization of separation processes in industries such as oil extraction and wastewater treatment.

Post a comment