← Back

Numerical analysis of Double Helical Heat Exchanger.

Associated with MIT Academy of Engineering, Alandi, Pune

Double-helical counterflow heat exchangers with different diameters were modeled using Fusion360 software and analyzed using ANSYS Fluent. Comparison was made between all models using different flow rate combinations to determine the effectiveness of the heat exchangers. The effectiveness - NTU method was utilized.

Skills: Computational Fluid Dynamics (CFD) · Heat Transfer · Heat Exchangers · Ansys Fluent

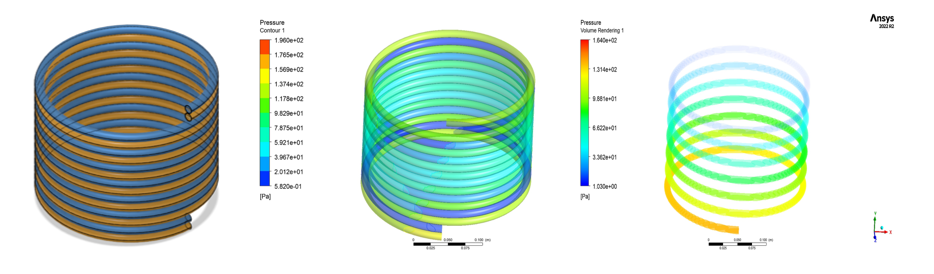

Fig. Generated Geometry (Using Fusion360) and Mesh (Using Ansys Meshing)

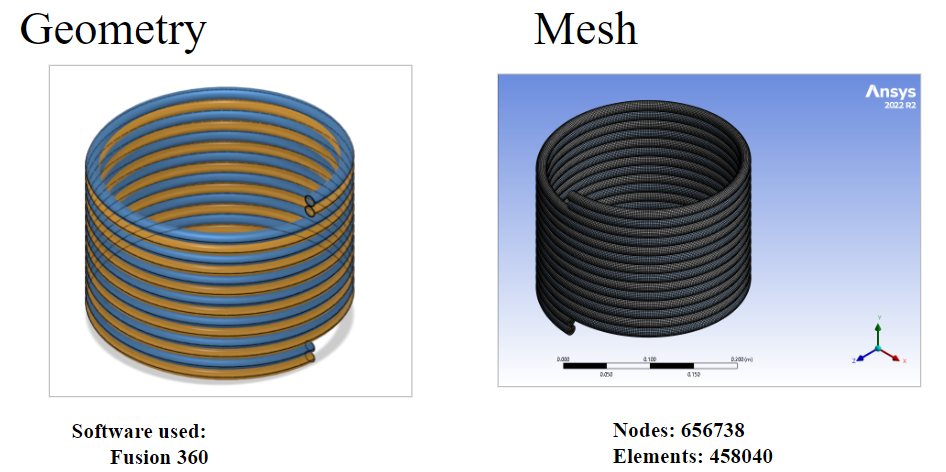

Fig. Fluid Temperature

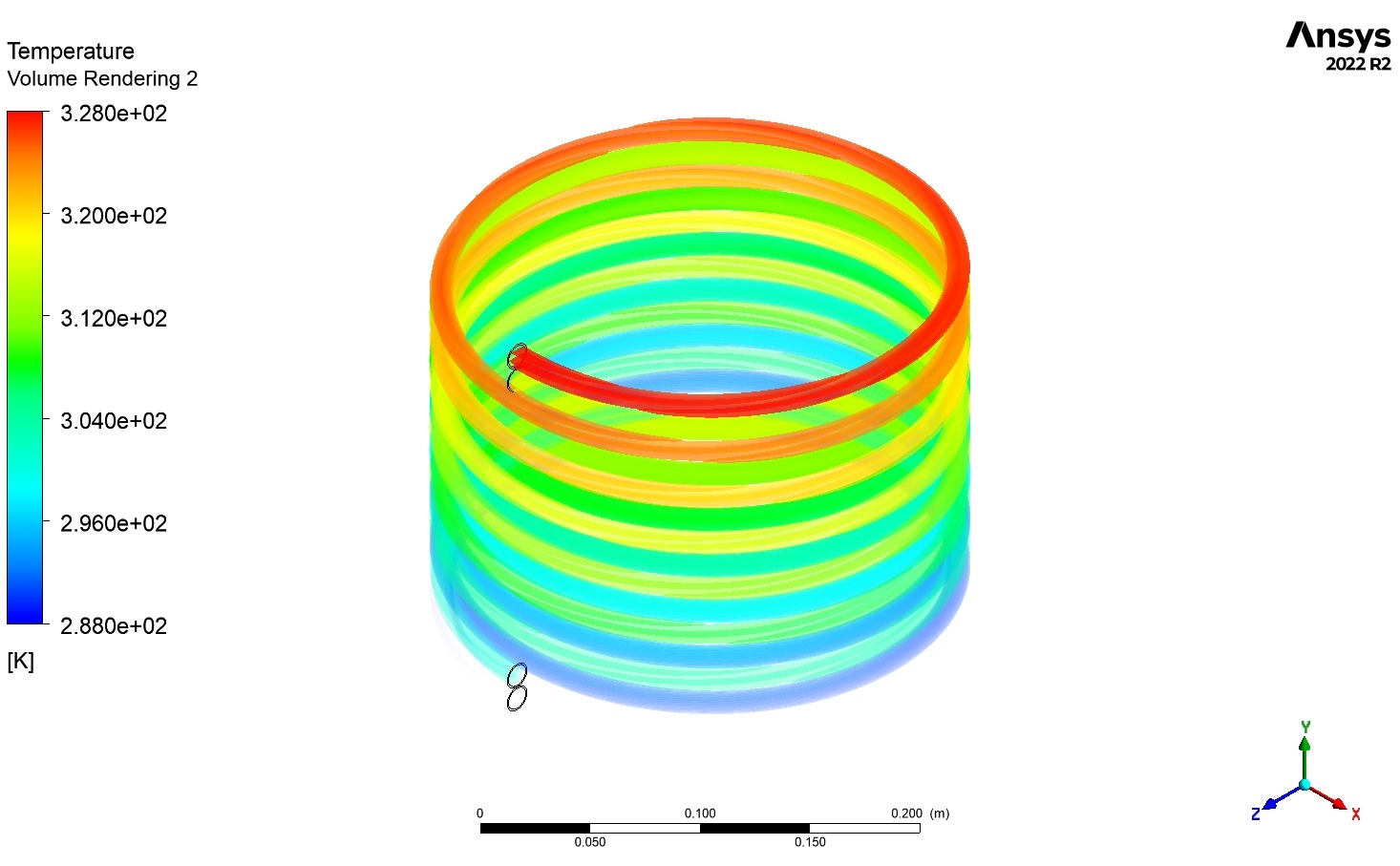

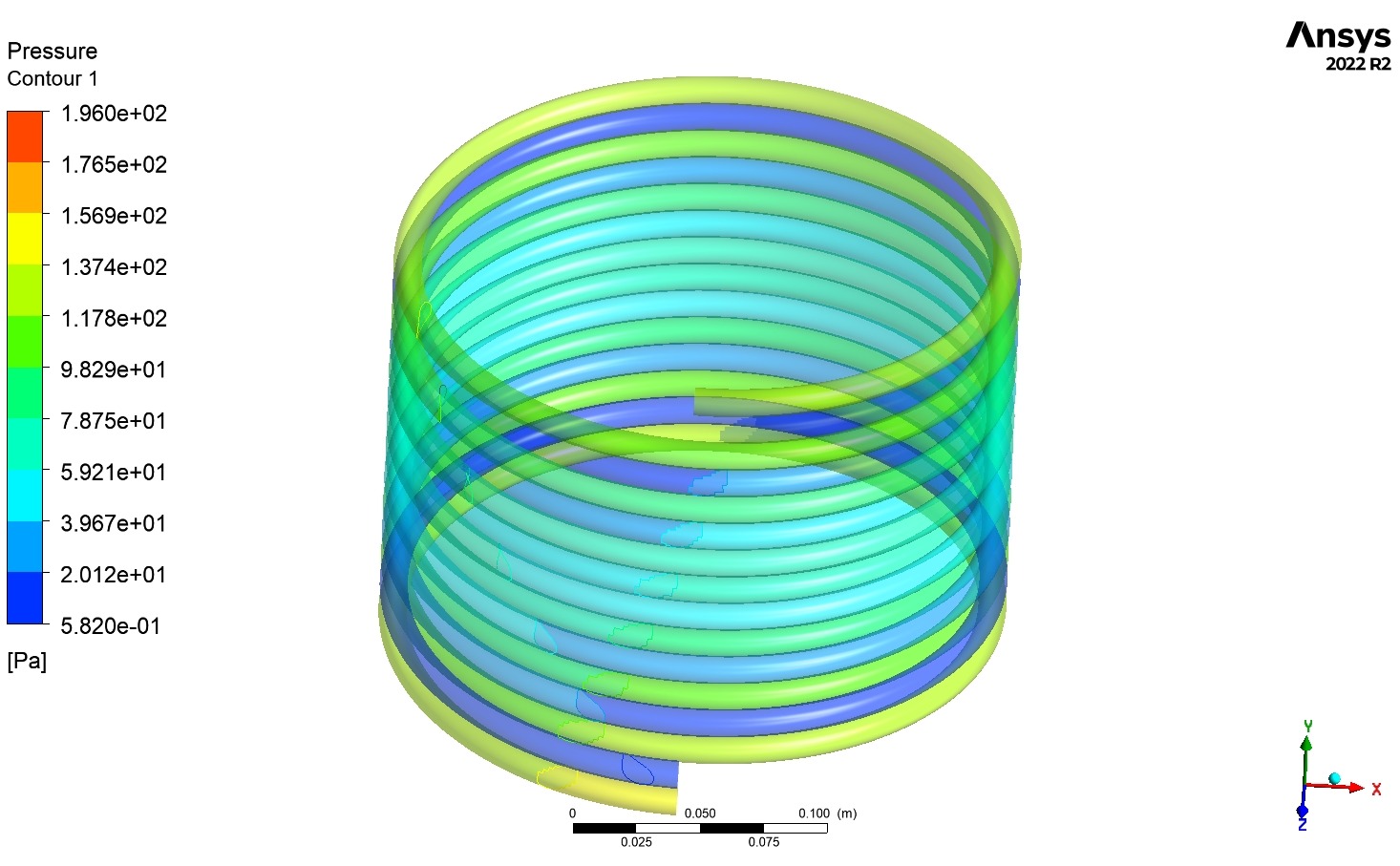

Fig. Pressure Drop

- Based on the CFD analysis and heat transfer theories, it was concluded that the double coiled helical counter flow heat exchanger with copper tubes is an effective method for enhancing heat transfer.

- The models created in Fusion360 with 0.5-inch and 5/8-inch diameter pipes were used to simulate different combinations of hot and cold water flow rates ranging from 0.5 to 1.5 LPM.

- The results show that the highest effectiveness was achieved when the hot water flow rate was 0.5 LPM and the cold water flow rate was 0.5, 1, or 1.5 LPM.

- Overall, the analysis demonstrates that the double coiled helical counter flow heat exchanger with copper tubes can be an efficient method for transferring heat, particularly when operating at the optimal flow rates.

0 Comments Add a Comment?