SAEDDC-2023

Dec 2022- Aug 2023

Our journey in the national-level aeromodelling competition organized by SAE India was a testament to teamwork, innovation, and dedication. Tasked with designing and fabricating an Unmanned Aerial Vehicle (UAV) that met strict specifications, our team, Blitzkrieg, embarked on a mission to push the boundaries of aerial technology. With a comprehensive approach encompassing research, design, manufacturing, and testing, we aimed to surpass expectations and showcase our expertise.

Team Overview

Team Blitzkrieg comprised ten dedicated members, each contributing their unique skills and expertise under the guidance of our esteemed faculty coordinator, Mr. S. B. Powar. From engineering to management, every team member played a vital role in shaping our project's success. Through effective collaboration and communication, we fostered a dynamic environment conducive to innovation and problem-solving.

Missions and Constraints

Our mission was clear: to design and manufacture a UAV capable of meeting stringent specifications outlined by the Society of Automotive Engineers India Southern Section. These specifications included weight limitations, size restrictions, power source requirements, and performance benchmarks. Additionally, we faced constraints regarding timeline, resources, and technical challenges inherent in aerospace engineering. Despite these obstacles, we remained undeterred in our pursuit of excellence.

My Role

Within Team Blitzkrieg, I had a multifaceted role encompassing Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA), and manufacturing processes. Additionally, I actively participated in other aspects of the project, including report preparation, presentation, 3D design, and project management. This holistic involvement allowed me to contribute significantly to our team's success while gaining invaluable experience across various disciplines.

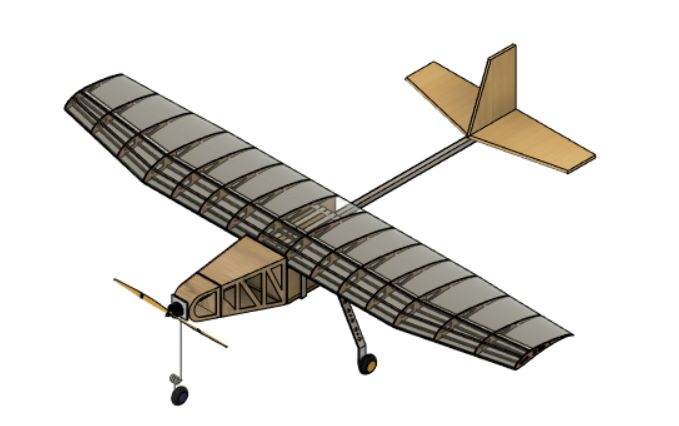

Aircraft Details

Our UAV featured a semi-tapered wing with the s1223 airfoil, a semi-monocoque fuselage, and a conventional-type empennage. Powered by Li-Po batteries and equipped with BLDC motors for thrust, our aircraft boasted efficient control surfaces operated by servomotors. These design elements were meticulously selected and integrated to ensure structural integrity, aerodynamic efficiency, and optimal performance throughout the competition.

Awards and Rankings

Overall Ranking: AIR 7

Design Report: AIR 1

Technical Presentation: AIR 3

Post a comment